Select an Optical Filter to Suit Changing Conditions

Article Featured in Industrial PhotonicsOptical filters have long been critical components in traditional machine vision applications. They maximize contrast, improve color and subject recognition, or otherwise control light reflected from an object under inspection. Typically, filters are used for machine vision tasks that do not vary much from product to product or from one subject to the next. However, recent advances in sensors, artificial intelligence, human-robot interaction and other technologies have led to the use of machine vision in more flexible applications such as sorting, material handling and automated assembly. When choosing a filter for these applications, consider the following.

Tip 1: Control the variability of ambient light.

One of the difficulties in successfully integrating vision and robots is inconsistent lighting. Vision systems mounted on robotic arms, including 3D systems, often have to deal with constantly changing lighting conditions because of subject matter that is presented at different angles and viewed from varying perspectives. Particularly as collaborative robotics become more prevalent, caging and shrouding of the system will be unnecessary and relatively costly. Instead, mounting appropriate lighting and a camera with a matching bandpass filter on a robotic arm will effectively neutralize much of the variability of ambient light associated with object orientation.

Tip 2: Use stable filters to avoid short shifting.

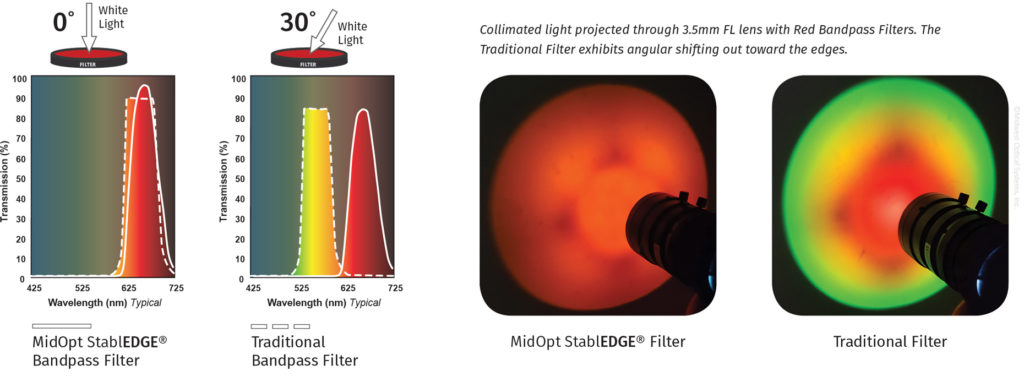

As viewing positions are adjusted, changing angles can create a challenge for traditional coated interference bandpass filters because of “blue shifting.” At wider viewing and lighting incidence angles, changes are imposed on the filter passband. Shorter wavelength ambient light is passed and LED or laser diode illumination is attenuated. For vision-guided robotic arms, the effect is seen in the intermittent darkening or lightening of the image toward the edges of the field of view as the automated system progresses through its tasks. It is particularly common when the camera uses a lens with a focal length of 12mm or less — statistically about 50 percent of the time. For this reason, consider using a filter design that incorporates an absorptive filter glass to form a portion of the passband. Absorptive filter glasses are not subject to the blue shifting anomaly.

Traditionally, as the incident angle imposed by the lens’ field of view increases, a filter’s passband shifts, allowing shorter wavelength light to pass, commonly referred to as blue shifting or short shifting. In contrast, some absorptive filter glass designs provide lower wavelength blocking, which significantly minimizes the effects of blue shifting.

Traditionally, as the incident angle imposed by the lens’ field of view increases, a filter’s passband shifts, allowing shorter wavelength light to pass, commonly referred to as blue shifting or short shifting. In contrast, some absorptive filter glass designs provide lower wavelength blocking, which significantly minimizes the effects of blue shifting.

Tip 3: Reduce specular glare with polarizers.

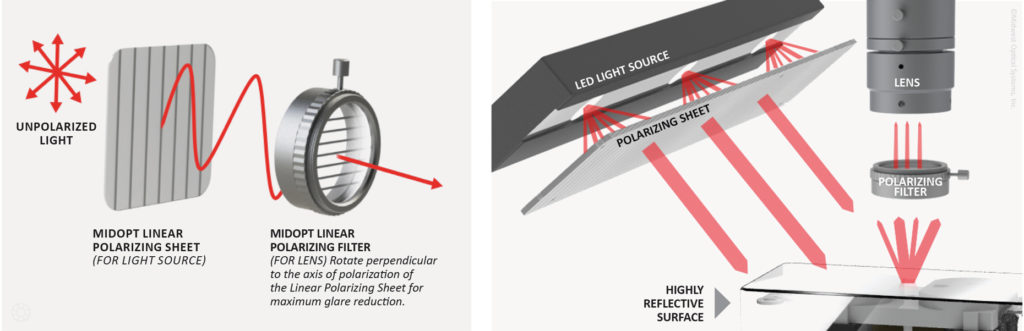

Another common imaging problem encountered as a robotic arm maneuvers around an object is the appearance of intermittent glare off of glass, glossy or polished plastic, or liquid-covered or painted surfaces. Polarizers will generally not eliminate specular reflections from polished metal surfaces. In these instances, the reflected light usually originates from the illuminator employed by the vision system. Fortunately, with the light and camera installed together on the arm, this problem is often easily controlled by mounting linear polarizing filters both on the camera lens and the light. There are two important attributes to look for in polarizing filters for machine vision. One is a locking feature to fix the orientation of the filter on the lens and to prevent it from moving over time. The other is a filter that maximizes glare reduction through a higher extinction ratio. Polarizing filters for consumer photography are used for purposes beyond glare reduction, and are often not ideal.

Another point to keep in mind is that polarizers are waveband-specific. Standard polarizing filters will only work in the visible range. The polarizer’s effective wavelength range should cover the range used in the application. For example, for infrared usage, select linear polarizers that are designed to work in the specific range of the near-IR that your light source operates within. Not only are infrared and other non-visible polarizers far more expensive, it may be worth keeping in mind that they generally will not be as good at extinguishing glare as their better visible-wavelength counterparts. Finally, when a polarizing material is used directly over high-brightness LED lighting, it is almost always advisable to select a material that is resistant to higher temperatures. A dye or wire grid polarizer should be considered. A dye polarizer, particularly when laminated between glass, will be durable and less costly than a wire grid polarizer.

Placing a sheet of linear polarizing material over the light source and a rotating polarizer over the camera lens often can greatly reduce reflected glare.

Placing a sheet of linear polarizing material over the light source and a rotating polarizer over the camera lens often can greatly reduce reflected glare.

Tip 4: Eliminate chromatic aberrations.

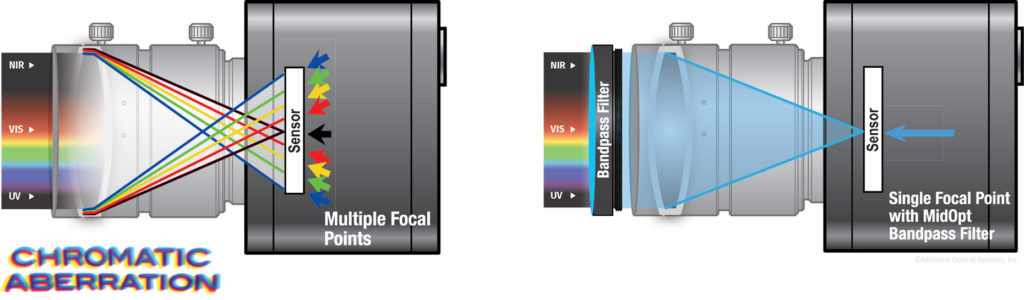

Because of ever-shrinking CMOS sensor pixel sizes and applications with higher resolution requirements, lens performance in recent years has become more of a limiting factor. When working in color, different wavelengths of white light will focus at different distances when they are imaged onto the camera’s sensor. The various colors of the visible spectrum correspond to different wavelengths. This slight defocusing is referred to as chromatic aberration. If a color camera is not essential, using a monochrome camera and suitable bandpass filter can help significantly by essentially eliminating all but one wavelength of light that needs to be focused. Overall brightness and contrast can also be improved, which in turn will always lead to a sharper image.

A bandpass filter will reduce the range of wavelengths of light that are transmitted through a lens, which can appreciably improve focus.

A bandpass filter will reduce the range of wavelengths of light that are transmitted through a lens, which can appreciably improve focus.

Author: Barry Warzak, President, Midwest Optical Systems (MidOpt)

This article was featured in Industrial Photonics.