Monochrome Imaging

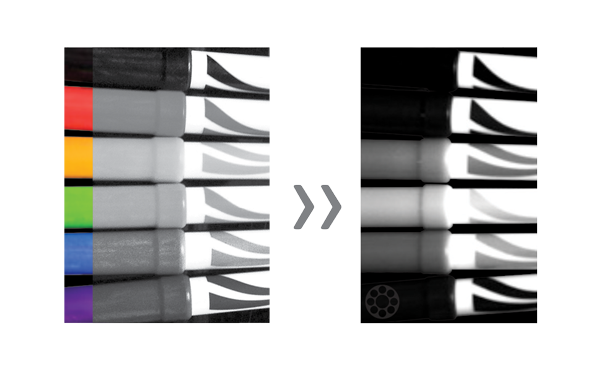

Many assume that color imaging is more advanced than black-and-white, or monochrome, imaging. But that’s not always true when it comes to machine vision.

Many assume that color imaging is more advanced than black-and-white, or monochrome, imaging. But that’s not always true when it comes to machine vision.

Monochrome cameras combined with high-quality optical filters:

› can offer higher contrast and better resolution

› provide better signal-to-noise ratio

› are sensitive to near-ultraviolet, visible and near-infrared spectrums

› provide flawless results

These features give monochrome cameras a significant advantage when it comes to optical character recognition and verification, barcode reading, scratch or crack detection, wavelength separation and more. Depending on your application, monochrome cameras can be three times more efficient than color cameras.

-

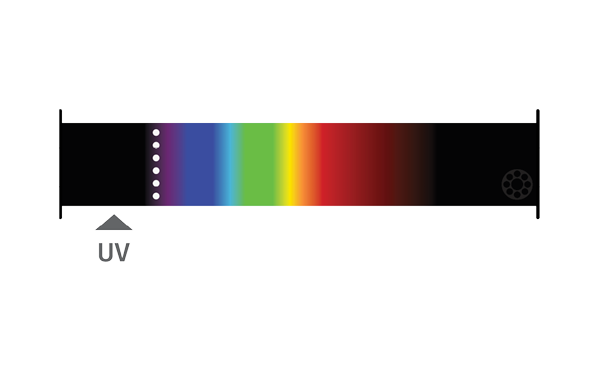

Wavelength (Color) Separation

Bandpass Filters are a great tool for selectively passing (highlighting) or blocking (darkening) color to maximize contrast or grayscale in a monochrome image. Test the effects of monochromatic illumination by using a broad spectrum light source and a MidOpt Bandpass Filter to determine the proper wavelength for an application.

-

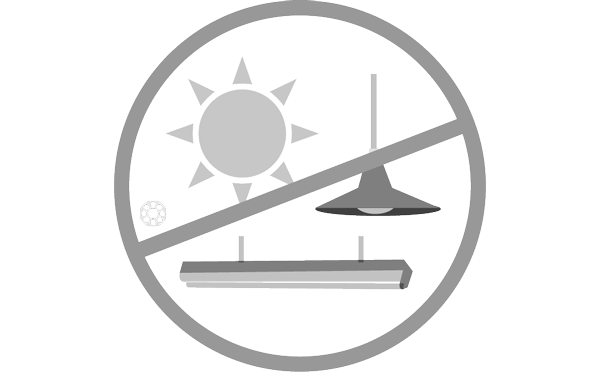

Block Unwanted Light

Unwanted light can impact inspection quality and consistency. MidOpt filters can improve imaging by blocking interfering light that surrounds the application and only passing the light needed for inspection. This results in higher contrast and resolution and improves overall vision system accuracy.

-

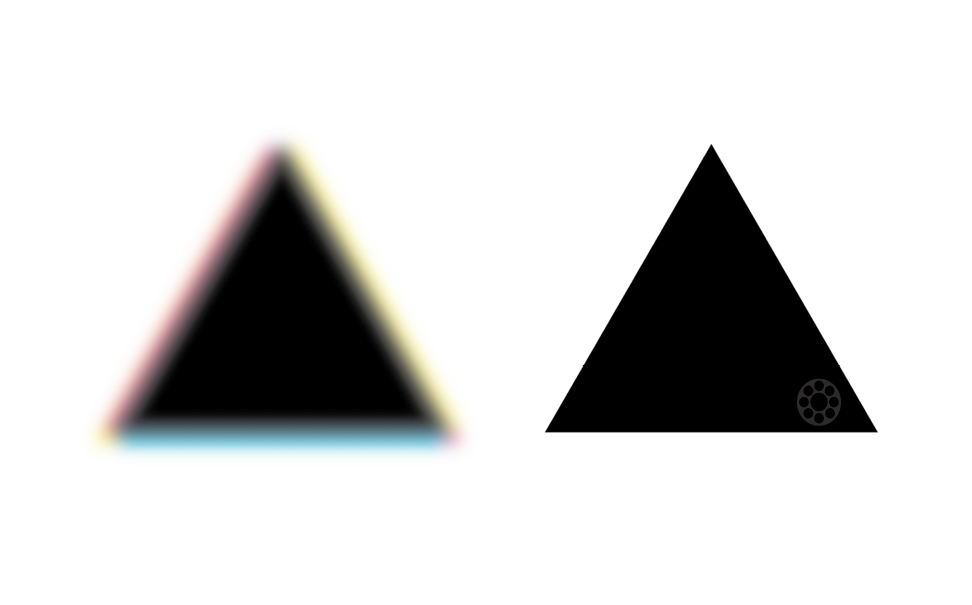

Increased Resolution

Chromatic aberration is a type of distortion that occurs when a lens attempts to focus all colors (wavelengths) over multiple imaging planes. By limiting the wavelength range entering the optical system significant resolution improvements can be made, especially if there is substantial ultraviolet or near-infrared light.

-

Glare Reduction

Light reflected from a polished, wet or oily surface can create glare. MidOpt Polarizing Filters can quickly and easily reduce specular glare. When possible, it’s recommended to use a polarizing filter over the lens and polarizing film over the light source. To secure alignment, a locking screw is included on all polarizer rotating mounts.

-

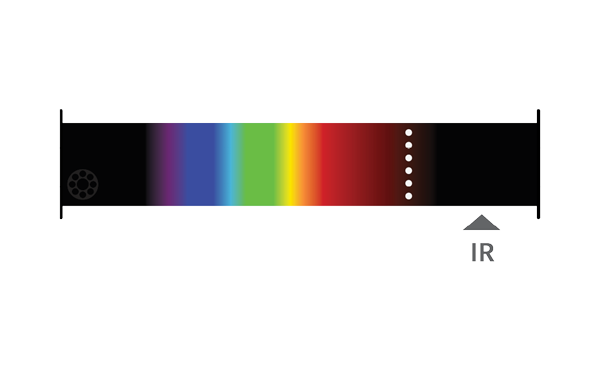

Near-Infrared Imaging

The human eye is not sensitive to near-infrared wavelengths, but a camera is. By using a near-infrared bandpass filter and blocking the visible spectrum, the camera is transformed into a near-infrared imager. When paired with an infrared light source, contrast results can be significantly enhanced.

-

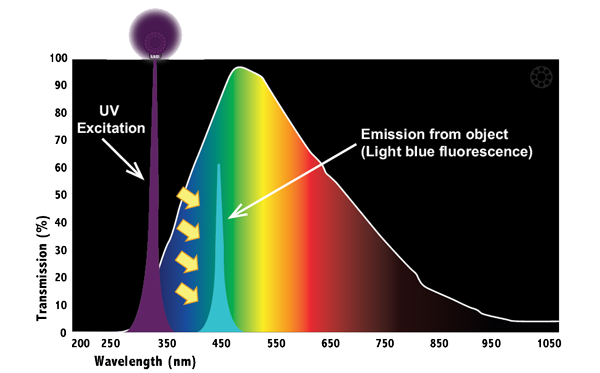

Fluorescence

Ultraviolet excitation light sources are commonly used in fluorescence applications but can pose a challenge for any vision system when trying to reliably detect luminescent emissions. MidOpt filters are used to block the excitation ultraviolet light source and pass only the fluorescence emission, eliminating illumination cross talk and resulting in maximum contrast.

-

Ultraviolet Imaging

Similar to infrared imaging, the human eye is not sensitive to ultraviolet wavelengths. When an ultraviolet light source is paired with a Bandpass Filter, results can be drastic. Ultraviolet Pass Filters can be placed over lenses and are sometimes placed over ultraviolet light sources to trim or block the output of visible light in fluorescence imaging applications.

-

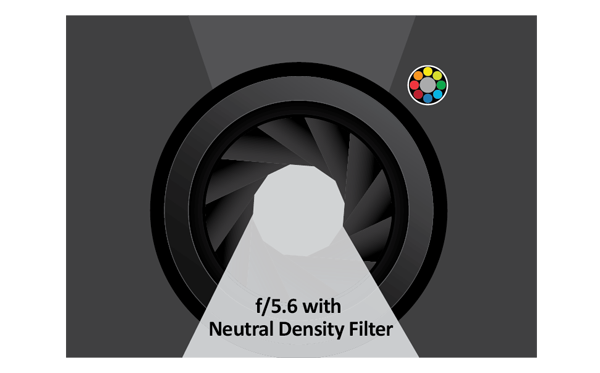

Exposure Control

Neutral Density Filters allow for longer exposure times by reducing the amount of light entering the lens and camera. They can reduce light intensity (saturation) throughout the visible and near-infrared spectrum without affecting color or contrast. MidOpt offers both absorptive and low-reflectivity Neutral Density Filters.

-

Lens Protection

Protective Filters act as windows or dust covers for lenses, filters, sensors, cameras or lighting. These filters are available in both glass and optical-grade acrylic. Acrylic Protective Filters are a great, inexpensive solution for FDA and EMA applications to eliminate the possibility of broken glass contaminating items under inspection.